|

|

|

|

|||

|

|

||||||

|

Operating Recommendations |

|

Coolant: Dressing: Truing: |

| Grit size and its Relationship to Finish | |||

| Mesh Size | Average Particle Size |

Application | Resulting Finish (Approximate RMS) |

| 80 | .009" | Roughing only - finish quality irrelevent | 15 |

| 100 | .006 | General roughing - all types of grinding | 10-15 |

| 120 | .005 | General purpose - fast stock removal | 7-12 |

| 150 | .004 | General purpose - all types of grinding | 5-10 |

| 180 | .003 | Intermediate-faster cut than finishing wheel | 4-8 |

| 220 | .0025 | Finish grinding - all types | 4-6 |

| 320 | .0012 | Power fluting | 4 |

| 400 | .0009 | Tool primaries | 3 |

| 500 | .0007 | Increasingly finer finishes | 3 |

| 600 | .0005 | Finer finishes for gages, roll, tools, etc. | 1-2 |

| 800 | .0003 | Polishing gages, rolls, dies, etc. | 1-2 |

| 1000 | .0002 | Finer polishing of gages, rolls, dies, etc. | 1 |

Resin & Metal Bond - Diamond & CBN Grinding Wheels [top]

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Type

D1A1 Diamond in Periphery |

.jpg) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Please specify abrasive type, size & concentration; as well as hole diameter and material being machined. Many other sizes and styles available. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Please specify abrasive type, size & concentration; as well as hole diameter and material being machined. Many other sizes and styles available. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Please specify abrasive type, size & concentration; as well as hole diameter and material being machined. Many other sizes and styles available. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Please specify abrasive type, size & concentration; as well as hole diameter and material being machined. Many other sizes and styles available. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

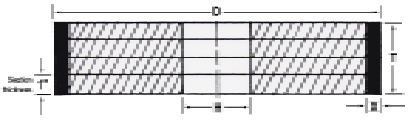

| Type

D1A1 Sectional Wheels with Straight Joints Diamond in Periphery Centerless Grinding |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

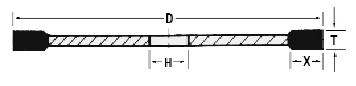

| Type

D1A1R Continuous Rim Cut-Off Blades Resin or Metal Bond |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

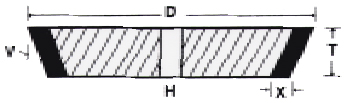

| Type

D1V1 Straight "V" Face (Bevelled) Diamond in Periphery |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Type D4A2P Diamond in Rim Aluminum Body |

|

|||||||

| Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Hole Diameter (H") |

Rim Width (W") |

Core Thickness (E") |

Core Flat (J") |

Back Angle (S°) |

Diamond Depth (X") |

| 33-0400 | 4" | 5/16" | S P E C I F Y |

1/8" | 1/4" | 2-3/8" | 15° | 1/16" |

| 33-0401 | 1/8" | |||||||

| 33-0405 | 3/16" | 1/16" | ||||||

| 33-0406 | 1/8" | |||||||

| 33-0410 | 1/4" | 1/16" | ||||||

| 33-0411 | 1/8" | |||||||

| 33-0600 | 6" | 5/16" | 1/8" | 1/4" | 2-1/2" | 8° | 1/16" | |

| 33-0601 | 1/8" | |||||||

| 33-0605 | 3/16" | 1/16" | ||||||

| 33-0606 | 1/8" | |||||||

| 33-0610 | 1/4" | 1/16" | ||||||

| 33-0611 | 1/8" | |||||||

| 33-0620 | 6" | 7/16" | 1/8" | 3/8" | 2-1/2" | 11° | 1/16" | |

| 33-0621 | 1/8" | |||||||

| 33-0625 | 3/16" | 1/16" | ||||||

| 33-0626 | 1/8" | |||||||

| 33-0630 | 1/4" | 1/16" | ||||||

| 33-0631 | 1/8" | |||||||

| 33-0850 | 8" | 1/2" | 1/8" | 7/16" | 3" | 9° | 1/16" | |

| 33-0851 | 1/8" | |||||||

| 33-0855 | 3/16" | 1/16" | ||||||

| 33-0856 | 1/8" | |||||||

| 33-0860 | 1/4" | 1/16" | ||||||

| 33-0861 | 1/8" | |||||||

| Type D2A2T Threaded Holes Diamond in Rim |

|

|||||||||

| Please specify hole size, bolt circle diameter, number of bolt holes, diameter & depth of bolt holes, and thread size in holes. | ||||||||||

| Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Rim Width (W") |

Diamond Depth (X") |

Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Rim Width (W") |

Diamond Depth (X") |

|

| 09-0600 | 6" | 7/8" | 1/2" | 1/8" | 09-1010 | 10" | 3/4" | 1/2" | 1/8" | |

| 09-0601 | 1/4" | 09-1011 | 1/4" | |||||||

| 09-0610 | 5/8" | 1/8" | 09-1030 | 1" | 1/8" | |||||

| 09-0611 | 1/8" | 09-1031 | 1/4" | |||||||

| 09-0620 | 3/4" | 1/8" | 09-1100 | 11" | 3/4" | 1/8" | ||||

| 09-0621 | 1/4" | 09-1101 | 1/4" | |||||||

| 09-0950 | 250mm | 34mm | 8mm | 1/8" | 09-1110 | 1" | 1/8" | |||

| 09-0951 | 1/4" | 09-1111 | 1/4" | |||||||

| 09-0960 | 10mm | 1/8" | 09-1800 | 18" | 3/4" | 1/8" | ||||

| 09-0961 | 1/4" | 09-1801 | 1/4" | |||||||

| 09-1000 | 10" | 3/4" | 1/4" | 1/8" | 09-1810 | 1" | 1/8" | |||

| 09-1001 | 1/4" | 09-1811 | 1/4" | |||||||

| Type D2A2 Diamond in Rim |

|

||||

| Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Rim Width (W") |

Hole Size |

Diamond Depth (X") |

| 09A-0500 | 5" | 1/4" | 1" | 3 or 3.018 | 1/32" |

| 09A-0501 | 1/16" | ||||

| When requesting a price or placing an order, please provide us with the information listed below: D = Wheel Diameter |

|

Type D3A1 |

|

Type D14A1 |

| Type D6A2 Diamond in Rim (Without Bolt Holes) |

|

|||||

| Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Hole Diameter (H") |

Rim Width (W") |

Back Thickness (E") |

Diamond Depth (X") |

| 11-0310 | 3" | 3/4" | S P E C I F Y |

1/4" | 3/8" | 1/16" |

| 11-0311 | 1/8" | |||||

| 11-0410 | 4" | 1/2" | 1/16" | |||

| 11-0411 | 1/8" | |||||

| 11-0610 | 6" | 3/16" | 1/16" | |||

| 11-0611 | 1/8" | |||||

| Type D6A2C Diamond in Rim (With Bolt Holes) |

|

|||||||||||

| Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Rim Width (W") |

Back Thickness (E") |

Diamond Depth (X") |

Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Rim Width (W") |

Back Thickness (E") |

Diamond Depth (X") |

|

| 13-0605 | 6" | 3/4" | 1/4" | 7/16" | 1/16" | 13-0705 | 7" | 1-1/4" | 1" | 1/2" | 1/16" | |

| 13-0606 | 1/8" | 13-0706 | 1/8" | |||||||||

| 13-0615 | 3/8" | 1/16" | 13-0715 | 3/4" | 3/4" | 7/16" | 1/16" | |||||

| 13-0616 | 1/8" | 13-0716 | 1/8" | |||||||||

| 13-0625 | 1/2" | 1/16" | 13-1005 | 10" | 1" | 3/4" | 1/16" | |||||

| 13-0626 | 1/8" | 13-1006 | 1/8" | |||||||||

| 13-0635 | 3/4" | 1/16" | 13-1015 | 1" | 1/16" | |||||||

| 13-0636 | 1/8" | 13-1016 | 1/8" | |||||||||

| 13-0645 | 1" | 1/16" | 13-1405 | 14" | 1/16" | |||||||

| 13-0646 | 1/8" | 13-1406 | 1/8" | |||||||||

| 13-0655 | 1-1/4" | 3/4" | 1/16" | |||||||||

| 13-0656 | 1/8" | |||||||||||

| Type D6A2H Diamond in Rim (With Bolt Holes) |

|

Please specify bolt circle, hole diameter, and # of holes. | ||||

| Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Hole Diameter (H") |

Rim Width (W") |

Back Thickness (E") |

Diamond Depth (X") |

| 12-0500 | 5" | 1" | 1-1/4" | 1-1/16" | 1/2" | 1/16" |

| 12-0501 | 1/8" | |||||

| Type D6A9 Diamond in Periphery |

|

Type D9A3H Diamond in Rim (With Bolt Holes) Type D9A3 (Without Bolt Holes) |

|

||||||||||

| Order # | Wheel Diameter (D') |

Wheel Thickness (T") |

Back Thickness (E") |

Inside Flat (K") |

Insert Length (U") |

Diamond Depth (X") |

Order # | Wheel Diameter (D') |

Wheel Thickness (T") |

Rim Width (W") |

Back Thickness (E") |

Diamond Depth (X") |

|

| 10-0310 | 3' | 1-1/2" | 3/8" | 2-1/4" | 1/2" | 1/16" | 14-0605 | 6' | 1" | 1/4" | 1/2" | 1/16" | |

| 10-0311 | 1/8" | 14-0606 | 1/8" | ||||||||||

| 10-0404 | 4' | 3/4" | 9/32" | 3-3/16" | 1/4" | 1/16" | 14-0615 | 3/8" | 1/16" | ||||

| 10-0405 | 1/8" | 14-0616 | 1/8" | ||||||||||

| 10-0407 | 3/8" | 1/16" | 14-0625 | 1/2" | 1/16" | ||||||||

| 10-0408 | 1/8" | 14-0626 | 1/8" | ||||||||||

| 10-0410 | 1-1/4" | 1/2" | 3" | 1/16" | 14-0705 | 7' | 1/4" | 1/16" | |||||

| 10-0411 | 1/8" | 14-0706 | 1/8" | ||||||||||

| 10-0600 | 6' | 1-1/2" | 3/8" | 5" | 1/4" | 1/16" | 14-0715 | 3/8" | 1/16" | ||||

| 10-0601 | 1/8" | 14-0716 | 1/8" | ||||||||||

| 10-0605 | 1/2" | 1/16" | |||||||||||

| 10-0606 | 1/8" | ||||||||||||

| Type D11V9 Flaring Cup Diamond in Periphery |

|

Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Back Thickness (E") |

Inside Flat (K") |

Back Angle (S°) |

Insert Length (U") |

Diamond Depth (X") |

| 17-0305 | 3" | 1-1/4" | 1/2" | 1-3/4" | 70° | 3/8" | 1/16" | ||

| 17-0306 | 1/8" | ||||||||

| 17-0375 | 3-3/4" | 1-1/2" | 3/8" | 2-5/16" | 1/16" | ||||

| 17-0376 | 1/8" | ||||||||

| 17-0505 | 5" | 1-3/4" | 7/16" | 3-1/4" | 7/16" | 1/16" | |||

| 17-0506 | 1/8" |

| Type D12V9 Dish Diamond in Periphery |

|

|||||||||||||||

| Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Back Thickness (E") |

Inside Flat (K") | Dish Angle (B°) | Insert Length (U") | Diamond Depth (X") |

Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Back Thickness (E") |

Inside Flat (K") | Dish Angle (B°) | Insert Length (U") | Diamond Depth (X") |

|

| 18-0305 | 3" | 1/2" | 1/4" | 1-1/2" | 30° | 1/4" | 1/16" | 18-0415 | 4" | 7/8" | 3/8" | 2" | 45° | 3/8" | 1/16" | |

| 18-0306 | 1/8" | 18-0416 | 1/8" | |||||||||||||

| 18-0315 | 7/8" | 3/8" | 1-1/8" | 45° | 3/8" | 1/16" | 18-0605 | 6" | 3/4" | 3" | 30° | 1/4" | 1/16" | |||

| 18-0316 | 1/8" | 18-0606 | 1/8" | |||||||||||||

| 18-0405 | 4" | 1/2" | 1/4" | 2" | 30° | 1/4" | 1/16" | |||||||||

| 18-0406 | 1/8" | |||||||||||||||

| Type D11A2 Flaring Cup Diamond in Rim |

Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Rim Width (W") |

Back Thickness (E") |

Inside Flat (K") |

Back Angle (S°) |

Diamond Depth (X") |

| 15-0305 | 3" | 7/8" | 3/8" | 3/8" | 1-3/4" | 57° | 1/16" | |

| 15-0306 | 1/8" | |||||||

|

15-0315 | 1-5/16" | 75° | 1/16" | ||||

| 15-0316 | 1/8" | |||||||

| 15-0350 | 3-1/2" | 2-1/4" | 72° | 1/16" | ||||

| 15-0351 | 1/8" | |||||||

| 15-0405 | 4" | 1-1/4" | 1/2" | 1/2" | 66° | 1/16" | ||

| 15-0406 | 1/8" | |||||||

| 15-0505 | 5" | 1-3/4" | 3/8" | 3-1/8" | 69° | 1/16" | ||

| 15-0506 | 1/8" |

| Type D12A2 Diamond in Rim |

|

|||||||||||||||

| Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Rim Width (W") |

Back Thickness (E") |

Inside Flat (K") |

Dish Angle (B°) |

Diamond Depth (X") |

Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Rim Width (W") |

Back Thickness (E") |

Inside Flat (K") | Dish Angle (B°) | Diamond Depth (X") |

|

| 19-0305 | 3" | 1/2" | 1/4" | 5/16" | 1-1/4" | 28° | 1/16" | 19-0415 | 4" | 1/2" | 3/8" | 5/16" | 2" | 22° | 1/16" | |

| 19-0306 | 1/8" | 19-0416 | 1/8" | |||||||||||||

| 19-0315 | 7/8" | 1/8" | 3/8" | 1-3/8" | 45° | 1/16" | 19-0600 | 6" | 1" | 1/8" | 1/2" | 2-5/8" | 30° | 1/16" | ||

| 19-0316 | 1/8" | 19-0601 | 1/8" | |||||||||||||

| 19-0325 | 1/8" | 1/16" | 19-0605 | 3/16" | 1/16" | |||||||||||

| 19-0326 | 1/8" | 19-0606 | 1/8" | |||||||||||||

| 19-0335 | 3/8" | 1/16" | 19-0615 | 1/4" | 1/16" | |||||||||||

| 19-0336 | 1/8" | 19-0616 | 1/8" | |||||||||||||

| 19-0400 | 4" | 3/8" | 1/8" | 5/16" | 3-1/2" | 20° | 1/16" | 19-0625 | 3/8" | 1/16" | ||||||

| 19-0401 | 1/8" | 19-0626 | 1/8" | |||||||||||||

| 19-0405 | 1/2" | 1/4" | 2-1/4" | 27° | 1/16" | |||||||||||

| 19-0406 | 1/8" | |||||||||||||||

| Type D15A2 Diamond in Rim |

Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Rim Width (W") |

Back Thickness (E") |

Inside Flat (K") |

Dish Angle (B°) |

Diamond Depth (X") |

| 20-0605 | 6" | 3/4" | 1/8" | 7/16" | 3-1/8" | 45° | 1/16" | |

| 20-0606 | 1/8" | |||||||

|

20-0615 | 3/16" | 1/16" | |||||

| 20-0616 | 1/8" | |||||||

| 20-0625 | 1/4" | 1/16" | ||||||

| 20-0626 | 1/8" | |||||||

| 20-0635 | 3/8" | 1/16" | ||||||

| 20-0636 | 1/8" |

| Type D15V9 Diamond in Periphery |

|

|||||||

| Order # | Wheel Diameter (D") |

Wheel Thickness (T") |

Hole Diameter (H") |

Back Thickness (E") |

Inside Flat (K") |

Dish Angle (B°) |

Insert Length (U") |

Diamond Depth (X") |

| 22-0304 22-0306 |

3 | 1/2 | S P E C I F Y |

1/4 | 1-1/2 | 45° | 7/32 | 1/16 1/8 |

| 22-0405 22-0406 |

4 | 3/4 | 7/16 | 2-1/4 | 45° | 9/32 | 1/16 1/8 |

|

| 22-0600 22-0601 |

6 | 3/4 | 7/16 | 3 | 30° | 1/4 | 1/16 1/8 |

|

| 22-0605 22-0606 |

6 | 3/4 | 7/16 | 3-1/8 | 45° | 1/4 | 1/16 1/8 |

|

| Type DHH1 Diamond in Periphery |

|

Type DHH2 Diamond in Periphery |

|

|||||||||

| Order # | Hone Thickness (T") |

Hone Width (W") |

Hone Length (L") |

Insert Length (IL") |

Diamond Depth (X") |

Order # | Hone Thickness (T") |

Hone Width (W") |

Hone Length (L") |

Insert Length (IL") |

Diamond Depth (X") |

|

| 24-4010 | 1/4 | 3/8 | 4 | 1 | 1/16 | 25-4010 | 1/4 | 3/8 | 4 | 1 | 1/16 | |

| 24-4020 | 3/8 | 3/8 | 4 | 1 | 1/16 | 25-4020 | 3/8 | 3/8 | 4 | 1 | 1/16 | |

| 24-6020 | 3/8 | 3/8 | 6 | 1 | 1/16 | 25-6020 | 3/8 | 3/8 | 6 | 1 | 1/16 | |

Special Diamond or CBN Grinding Wheels designed for your specific needs. |

Dressing Sticks for Diamond Wheels | |

|

||

| Order # | Size " | |

| 26-001A | Aluminum Oxide 3/4 x 3/4 x 4 | |

| 26-001S | Silicon Carbide 1/2 x 1/2 x 6 | |

| SPECIFY: GRIT SIZE, CONCENTRATION, HOLE SIZE, AND MATERIAL |

| MANY OTHER SIZES AVAILABLE IN ALL STYLES |

Silver-Line Diamond Wheels [top]

| Designed for the small shop, where high volume usage is not important, but cost saving is. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

C = Coarse = 100 Grit M = Medium = 150 Grit F = Fine = 220 Grit • STOCKED ITEMS

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Diamond/CBN Wheel Truing Devices [top]

Unique, inexpensive, and easy to set up with or without magnetic chuck and comes in 2 grit sizes. Ideal for dressing smaller wheels. |

Diamond grit tools for truing Borazon™ wheels only. |

QUICK DRESS WITH MAGNETIC HOLDER. Economical, efficient, accurate way to true Borazon™ wheels. Can also be used for dressing angles and radii. |

||||||

| Item | Order No. | Stock | Item | Order No. | Stock | Item | Order No. | Stock |

| Dresser | 27-001 | • | 1/8 x 1/8 head | 30-001 | • | Holder | 101-001 | • |

| Coarse Wheel | 27-002 | • | 1/4 x 1/4 head | 30-002 | • | Quick Dress | 29-001 | • |

| Medium Wheel | 27-003 | • | 3/8 x 3/8 head | 30-003 | • | |||

Metal Bonded Core Drills [top]

For Glass, Ceramics & Quartz

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||