|

|

|

|

|||

|

|

||||||

| Application Info. PCD/PCBN | Devlieg Cartriges | PCD Inserts | Routers |

| Boring Tools | Endmills, PCD | PCD/CBN Grinding Wheels | Tuming Tools |

| CBN Inserts | Inserts | PCD/CBN Tools | Universal Tools |

| Commulator Tools | MRL 478 | Polycrystalline Tools | Vitrified/PCD/CBN Grinding Wheels |

|

Items shown with a "u" throughout catalog are stock items |

|||

Diamond Wheels for

Grinding PCD & CBN [top]

|

Wheel Type & Description

|

Resin Bond

|

Vitrified Bond

|

|

Devlieg

5" x 1" x 1-1/4" x 1" Rim |

100 or 125 Concentration

|

100 or 125 Concentration

|

|

Coborn (Metric)

150mm x 40mm x 40mm x 20mm Rim |

100 or 125 Concentration

|

100 or 125 Concentration

|

|

Ewag (Metric)

150mm x 40mm x 40mm x 20mm Rim |

100 or 125 Concentration

|

100 or 125 Concentration

|

|

Waida (Metric) 160mm x 40mm x 40mm x 20mm Rim |

100 or 125 Concentration | 100 or 125 Concentration |

|

Wheels for other grinders and other

shapes are available in depths of 1/8", 1/4" &

3/8". Specify grit size and concentration |

||

Cutting Tool Application Data [top]

|

CBN (Cubic Boron Nitride)

|

PCD (Polycrystalline Diamond)

|

|

Chrome moly steel rolls |

Aluminum and aluminum alloys

Brass Carbon Ceramics, unfired Chipboard Copper Epoxy resins Fiberboard Fiberglass composites; Epoxy, Phenolic & Vinyl Ester Gold Graphite Graphite Composites Magnesium and Magnesium alloys Phenolic Composites Plastics Rubber Silver Tungsten Carbide, presintered and sintered Zinc |

| Feed and Speed | |||||||

|

CBN

|

PCD

|

||||||

|

Material

|

Speed

(SFM) |

Feed Rate

Maximum (IPR) |

Depth of Cut

Maximum (In.) |

Material

|

Speed

(SFM) |

Feed Rate

Maximum (IPR) |

Depth of Cut

Maximum (In.) |

|

Colmonoy

Incoloy Inconel Iron, chilled cast Iron, grey cast Iron, high tinsel cast Monel Powdered Metal Rene 41 Rene 77 Steel, Alloy Steel, Bearing Steel, Carbon Steel, Die Steel, Tool Stellite Waspoloy |

550-650

750-900 500-650 130-260 1000-2600 200-500 550-650 500-650 500-650 450-550 200-500 200-500 200-500 160-350 160-350 550-650 550-650 |

.003

.006 .006 .032 .020 .060 .006 .016 .006 .006 .008 .008 .008 .008 .008 .006 .003 |

.060

.125 .125 .100 .040 .100 .125 .120 .125 .015 .020 .020 .020 .020 .020 .125 .060 |

Aluminum

Aluminum (14-18%) Aluminum (5-8%) Aluminum (8-12%) Babbit Brass Bronze Carbide, Sintered Carbon Carbon Composites Ceramics, High Alumina Copper Glass Fiber Wood and Composites |

3000-5000

1000-3000 4000-6000 3000-5000 800-1200 2000-4000 1000-1250 30-50 500-1000 500-2000 1240-2400 750-1500 750-1000 8000-13000 |

.005-.008

.002-.010 .010-.020 .005-.015 .003-.008 .003-.008 .003-.008 .004-.006 .005-.015 .005-.015 .001-.004 .003-.008 .001-.010 .010-.100 |

.005-.020

.003-.015 .005-.020 .005-.020 .005-.020 .005-.020 .005-.020 .0005-.005 .005-.030 .010-.100 .0005-.005 .005-.020 .001-.002 .010-.100 |

|

CNMA |

Dimensions

|

PCD Stock |

|

CPG |

Dimensions

|

PCD Stock

|

||||||||

|

Insert

|

I.C.

|

T

|

R

|

1/8 | 1/4 |

|

Insert

|

I.C.

|

T

|

R

|

1/8

|

1/4

|

|

|

CNMA-422

CNMA-432 CNMA-433 CNMA-434 |

.500

.500 .500 .500 |

.125

.188 .188 .188 |

.031

.031 .047 .063 |

u |

u |

CPG-421

CPG-422 |

.500

.500 |

.125

.125 |

.016

.031 |

u

u |

||||

|

DNGA |

Dimensions

|

PCD Stock |

SEC |

Dimensions

|

PCD Stock

|

|||||||||

|

Insert

|

I.C.

|

T

|

R

|

1/8 | 1/4 |

|

Insert

|

I.C.

|

T

|

R

|

1/8

|

1/4

|

|

|

DNGA-431

DNGA-432 DNGA-433 |

.500

.500 .500 |

.188

.188 .188 |

.016

.031 .047 |

u u |

u |

SEC-422

SEC-424 |

.500

.500 |

.125

.125 |

.031

.063 |

u

|

||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

VNMA |

Dimensions

|

PCD Stock

|

RPG-PCD |

Dimensions

|

PCD

Stock |

||||||||

|

Insert

|

I.C.

|

T

|

R

|

1/8

|

1/4

|

|

Insert

|

A

|

T

|

|||

|

VNMA-331

VNMA-332 VNMA-432 VNMA-442 VNMA-443 |

.375

.375 .500 .500 .500 |

.188

.125 .188 .250 .250 |

.016

.031 .031 .031 .047 |

u

|

RPG-32CP

RPG-42CP |

.375

.500 |

.125

.125 |

u

u |

|||||

|

SNG TOP LAYER

|

Dimensions

|

CBN

Stock |

RNG-CBN TOP LAYER |

Dimensions

|

PCD

Stock |

||||||||

|

Insert

|

A

|

T

|

R

|

|

Insert

|

A

|

T

|

|||||

|

SNG-322

SNG-422 SNG-432 |

.375

.500 .500 |

.125

.125 .187 |

.031

.031 .031 |

u

|

RNG-32

RNG-42 RNG-43 |

.375

.500 .500 |

.125

.125 .187 |

u

u |

|||||

|

SNG SOLID

|

Dimensions

|

CBN

Stock |

RNG-CBN SOLID |

Dimensions

|

PCD

Stock |

||||||||

|

Insert

|

A

|

T

|

R

|

|

Insert

|

A

|

T

|

|||||

|

SNG-322

SNG-422 |

.375

.500 |

.125

.125 |

.031

.031 |

u

u |

RNG-32

RNG-42 |

.375

.500 |

.125

.125 |

u

u |

|||||

|

Other Inserts Available PCD or CBN Tipped

|

|||||||||

|

CCMM

CCMT CCMW CDCD CNG CNGA CNMG CNMM CNMP CPGA CPGB |

CPGM

CPMA CPMT CPMW DCMM DCMT DCMW DDG DDGA DDGB DNEA |

DNGP

DNMG DNMM DNMP DPG DPGA DPGR DPGT DPMT DPMW DTGA |

EPMT

NPL NPR NPT NT NTB PM PNC PNG PPC PPG |

SCMT

SCMW SDE SDEB SEEN SEG SFA SFE SFG SM SNC |

SNE

SNEA SNMA SNMG SNMM SPC SPCE SPE SPEA SPMA SPMW |

TBEA

TBEE TBGD TBGE TCMM TCMT TCMW TD TDED TEC TEEN |

TFG

TM TNC TNEA TNMA TNMC TNMG TPC TPCE TPEA TPEE |

TPGA

TPGM TPMA TPMC TPMM TPMT TPMW TPV TX U3 VCMT |

VCMW

VNGA VNGP VNMG VNMP VPGA VPGR VPMA VPMT VTGA |

|

CBN inserts available

with chamfered edge .004 x 20 |

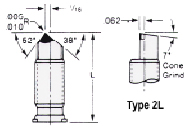

Boring Tools & Turning Tools [top]

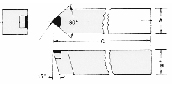

Style A |

Style B |

Style D |

||||||||||||

| Tool # | A | B | C | R | Tool# | A | B | C | R | Tool# | A | B | C | R |

| AR-6 u | 3/8 | 3/8 | 2-1/2 | 1/64 | BR-6 u | 3/8 | 3/8 | 2-1/2 | 1/64 | D6 u | 3/8 | 3/8 | 2-1/2 | 1/64 |

| AL-6 u | 3/8 | 3/8 | 2-1/2 | 1/64 | BL-6 u | 3/8 | 3/8 | 2-1/2 | 1/64 | |||||

| AR-8 u | 1/2 | 1/2 | 3-1/2 | 1/32 | BR-8 u | 1/2 | 1/2 | 3-1/2 | 1/32 | D8 u | 1/2 | 1/2 | 3-1/2 | 1/32 |

| AL-8 u | 1/2 | 1/2 | 3-1/2 | 1/32 | BL-8 u | 1/2 | 1/2 | 3-1/2 | 1/32 | |||||

Style E |

Style SRC |

Style SRE |

||||||||||||

| Tool # | A | B | C | R | Tool # | A | B | C | R | Tool # | A | B | C | R |

| E6 u | 3/8 | 3/8 | 2-1/2 | .010 | SRC-88 u | 1/2 | .240 | 1 | .187 | SRE-88 u | 1/4 | .240 | 1 | .187 |

| E8 u | 1/2 | 1/2 | 3-1/2 | .010 | SRC-1010 u | 5/16 | .300 | 1-1/4 | .235 | SRE-1010 u | 5/16 | .300 | 1-1/4 | .235 |

| MRL

478 Boring and Turning Tools |

Available in: PCD, CBN or Natural Diamond |

|||

| Shank | Style | Tool # Square |

Tool# Round |

|

| 3/8 | Left Hand | 500-3SL u | 500-SRL |  |

| 1/2 | Left Hand | 500-4SL u | 500-SRL | |

| 3/4 | Left Hand | 500-6SL | 500-SRL | |

| 3/8 | Right Hand | 500-3SR u | 500-SRR | |

| 1/2 | Right Hand | 500-4SR u | 500-SRR | |

| 3/4 | Right Hand | 500-6SR | 500-SRR | |

| 3/8 | V Style | 500-3SV u | 500-SRV | |

| 1/2 | V Style | 500-4SV u | 500-SRV | |

| 3/4 | V Style | 500-6SV | 500-SRV | |

| Universal Boring and Turning Tools | Available in: PCD, CBN or Natural Diamond |

|||||||||

| Complete Tool | Replacement Cap | |||||||||

| Size (in.) | Square Tool # |

Stock | Round Tool # |

Stock | Cap Tool # |

Stock |  |

|||

| PCD | Natural | PCD | Natural | PCD | Natural | |||||

| 3/8 | 501-030 | u | u | 501-031 | u | u | 501-130 | u | u | |

| 1/2 | 501-040 | u | u | 501-041 | u | u | 501-140 | u | u | |

| 5/8 | 501-050 | u | 501-051 | u | 501-150 | u | ||||

| 3/4 | 501-060 | u | 501-061 | u | 501-160 | u | ||||

| 1 | 501-070 | 501-071 | 501-170 | |||||||

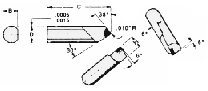

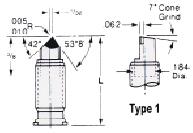

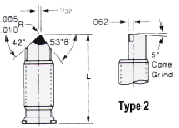

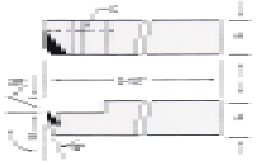

| PCD & CBN Boring Bars | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tools

available manufactured to customers requirements where B - 3/16"

5/8" or 3/4"; R = customers requirement; S = Customers requirement and/or Shank style is for boring to a square shoulder. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Devlieg PCD Cartridges | |||||||||||

|

|

|

|||||||||

| Cartridge Tool # |

Length | Cartridge Tool # |

Length | Cartridge Tool # |

Length | Cartridge Tool # |

Length | Cartridge Tool # |

Length | Cartridge Tool # |

Length |

| 3A1 | 1" | 3B1 | 27/32" | 3A2 | 1" | 3B2 | 27/32" | 3A2L | 1" | 3B2L | 27/32" |

| Shown in Size 3, Sizes 1 thru 9, as well as a 12â« top rake for cutting aluminum, are available. | |||||||||||

| PCD Commutator Turning Tools | ||

|

PCD Tip with Flat |

PCD Tip with Radius |

| Custom tools made to your specifications - quoted on request, also available in natural diamond. | ||

PCD Endmills, Routers and Form Tools [top]

Center Cutting |

Side Cutting |

||||

| Tool # | Diameter | # of Flutes | Flute Length | Center

or Side cutting |

|

| 504-01252 | u | .125" | 1 | .250 | Center |

| 504-01254 | .125" | 1 | .313 | Side | |

| 504-02501 | .250" | 2 | .156 | Center | |

| 504-02502 | u | .250" | 2 | .250 | Center |

| 504-02503 | .250" | 2 | .375 | Center | |

| 504-02504 | u | .250" | 2 | .500 | Side |

| 505-03751 | .375" | 2 | .250 | Center | |

| 504-03752 | u | .375" | 2 | .375 | Center |

| 504-03753 | .375" | 2 | .500 | Center | |

| 504-03754 | u | .375" | 2 | .500 | Side |

| 504-05001 | u | .500" | 2 | .250 | Center |

| 504-05002 | .500" | 2 | .500 | Center | |

| 504-05003 | .500" | 2 | 1.000 | Center | |

| 504-05004 | u | .500" | 2 | .500 | Side |

| 504-05005 | .500" | 2 | 1.000 | Side | |

| 504-07501 | u | .750" | 2 | .250 | Center |

| 504-07502 | .750" | 2 | .500 | Center | |

| 504-07503 | .750" | 2 | 1.000 | Center | |

| 504-07504 | .750" | 2 | .500 | Side | |

| 504-07505 | .750" | 2 | 1.000 | Side | |

| Other diameters, flute length & flute configurations available. Specify center or side cutting. Tools custom designed for today's abrasive or hard to cut modern composites, such as Kevlar(tm), carbon fiber or fiberglass. | |||||

|

| Custom form tools and/or form inserts for shapers. Custom routers and cutters manufactured to your prints and specifications. The benefits of this unique ultra-hard material are longer life, higher cut speed, and less downtime which equals lower cost per cut and greater productivity. |